In fluid management, self-priming pumps play a crucial role across various industries. This guide comprehensively explains self-priming pumps’ efficiency, applications, and recent innovations. Self-priming pumps have become indispensable due to their ability to prime a pump automatically without manual intervention, making them a preferred choice in many sectors. By the end of this guide, you will have a thorough understanding of self-priming pumps, how to prime a pump, and the innovations that have made priming a pump easier and more efficient than ever before.

What Are Self-Priming Pumps?

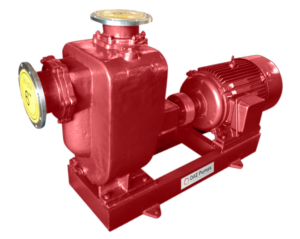

Self-priming pumps are a type of centrifugal pump designed to evacuate air from the suction line and create a partial vacuum to draw fluid into the pump, enabling it to prime itself. Unlike traditional pumps that require manual priming, self-priming pumps simplify the process and enhance operational efficiency.

Definition and Basic Principles

A self-priming pump can clear its passages of air if it becomes air-bound and resume pumping water without external attention. This capability is achieved by mixing air with water to create a pumpable fluid, expelling the air, and then continuing to pump only water.

Essential Components and Their Functions

Pump Casing: The housing that contains the pump components and fluid. The casing is designed to hold a certain amount of liquid necessary for the pump to prime itself.

Impeller: A rotating component that transfers energy from the motor to the fluid. It is crucial to create the centrifugal force needed to move the fluid through the pump.

Volute: A spiral casing that converts the kinetic energy from the impeller into pressure energy. This component helps efficiently move the fluid out of the pump.

Check Valve: This valve prevents backflow and maintains the pump’s prime. It ensures that the liquid remains in the pump casing and does not drain back into the suction line.

How They Differ from Other Types of Pumps

Traditional centrifugal pumps must be manually primed, requiring the suction line to be filled with fluid before starting. Self-priming pumps eliminate this need, providing convenience and efficiency, especially in applications where the pump might lose its prime frequently. This self-sufficiency in handling air makes them superior for many applications.

How Self-Priming Pumps Work

The self-priming process ensures that the pump can handle air and create a suction effect.

The Self-Priming Process

- Initial Fill: The pump casing must be filled with liquid before starting. This liquid acts as a sealant and helps to start the priming process.

- Air Handling: The impeller agitates the liquid in the casing, mixing it with the air in the suction line. The impeller’s rotation creates a mixture of air and liquid that is moved toward the discharge port.

- Air Separation: The mixture of air and liquid is moved to the discharge port, where the air is separated and expelled. The volute facilitates this process by helping segregate the air from the liquid.

- Recycling: The liquid is recirculated within the pump until all air is removed and a vacuum is created. This continuous process ensures that the pump remains primed.

- Continuous Operation: Once primed, the pump usually operates, pumping liquid efficiently. It can handle variations in the suction line without losing its prime.

Advantages of Self-Priming Pumps

Self-priming pumps offer numerous advantages, making them a preferred choice for various applications.

Efficiency and Cost-Effectiveness

Self-priming pumps reduce the need for manual intervention, lowering operational costs. They ensure quick and reliable start-ups, minimizing downtime. These pumps save time and labor costs by automating the priming process, leading to significant operational efficiencies.

Ease of Installation and Maintenance

Due to their robust design and self-priming capabilities, these pumps are straightforward to install and require less frequent maintenance. Their simplicity makes them easy to understand and maintain, even for personnel with basic training.

Reliability and Durability

Built to handle a variety of fluids, including those with solids, self-priming pumps are reliable and durable, ensuring long-term performance in demanding environments. Their ability to hold air and continue pumping makes them highly reliable in situations where other pumps might fail.

Comparison with Non-Self-Priming Pumps

Compared to non-self-priming pumps, self-priming pumps offer superior convenience and efficiency, particularly in applications where the suction line is prone to air entrainment. Non-self-priming pumps require manual intervention to re-prime, leading to increased downtime and operational costs.

Common Applications of Self-Priming Pumps

Self-priming pumps find applications in numerous industries due to their versatility and efficiency.

Industrial Uses

Chemical Processing:

Handle corrosive and abrasive fluids efficiently. Self-priming pumps are ideal for transferring aggressive chemicals and solvents, ensuring safe and efficient processing.

Wastewater Treatment:

Manage sludge and other challenging materials without frequent maintenance. These pumps treat sewage and industrial effluents, providing reliable performance under harsh conditions.

Agricultural Uses

Irrigation:

Provide consistent water supply for crops. Self-priming pumps are used in various irrigation systems, from small farms to large agricultural setups, ensuring efficient water distribution.

Slurry Handling:

Handle manure and other slurry materials efficiently in farming operations. This is crucial in livestock farms, where managing slurry efficiently is essential for maintaining hygiene and productivity.

Construction Uses

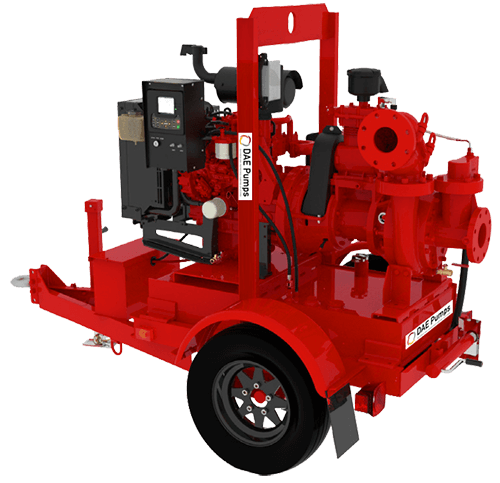

Dewatering:

It is essential for removing water from construction sites quickly. Self-priming pumps keep construction sites dry, preventing water accumulation that can delay projects.

Concrete Pumping:

Ensure timely delivery of concrete for construction projects. These pumps can handle the demanding task of moving concrete, ensuring consistent flow and preventing delays.

Marine Uses

Bilge Pumping:

Remove water from a vessel’s bilge to maintain safety. Self-priming pumps are critical for keeping ships’ buoyancy and stability by efficiently removing bilge water.

Ballast Water Management:

Ensure the stability and safety of ships through efficient ballast water management. These pumps help adjust the ballast water levels, which is crucial for maintaining the ship’s stability and compliance with international regulations.

Types of Self-Priming Pumps

There are two main types of self-priming pumps: centrifugal self-priming pumps and positive displacement self-priming pumps.

Centrifugal Self-Priming Pumps

These pumps use an impeller to create centrifugal force, allowing them to efficiently handle large volumes of fluid. They are ideal for applications requiring high flow rates and moderate pressure. Centrifugal self-priming pumps are commonly used in water treatment, irrigation, and various industrial processes.

Positive Displacement Self-Priming Pumps

These pumps move fluid using mechanisms such as gears, diaphragms, or pistons. They are suitable for applications requiring precise flow control and high pressure. Positive displacement self-priming pumps are used in chemical dosing, oil and gas, and food processing, where precise fluid handling is crucial.

Comparisons and Best-Use Scenarios

Centrifugal Self-Priming Pumps: Best for large-scale applications with high flow rate requirements. They are efficient and can handle a variety of fluids, including those with solids.

Positive Displacement Self-Priming Pumps: Ideal for precise dosing and high-pressure applications. They provide consistent flow rates and are capable of handling highly viscous fluids.

Key Features to Consider When Selecting a Self-Priming Pump

Several factors should be considered to ensure optimal performance when choosing a self-priming pump.

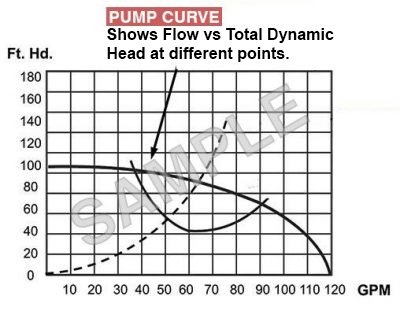

Flow Rate and Pressure Requirements

Match the pump’s capabilities with the application’s needs to ensure efficient operation. A pump with the correct flow rate and pressure will perform better and be more cost-effective. Consider the maximum and minimum flow rates required for your application and select a pump that can handle these variations.

Material Compatibility and Durability

Select pumps made from materials resistant to the fluid being handled to avoid corrosion and wear. This ensures longevity and reliability in operation. For example, pumps handling corrosive chemicals should be made from materials like stainless steel or specialized plastics.

Suction Lift Capability

Ensure the pump can handle the required suction lift to avoid cavitation and maintain efficiency. The higher the suction lift, the more versatile the pump. Cavitation can cause significant damage to the pump and reduce its lifespan, so it’s crucial to select a pump with the appropriate suction lift capacity for your application.

Energy Efficiency and Operational Cost

Choose pumps with high energy efficiency to reduce long-term operational costs. Energy-efficient pumps are not only cost-effective but also environmentally friendly. Look for pumps with energy-saving features and certifications to ensure they meet your efficiency requirements.

Brand Reputation and Customer Support

Opt for reputable brands that offer reliable products and excellent customer support. Good customer support can be crucial in troubleshooting and maintaining your pump. Research customer reviews and ask for recommendations to ensure you choose a brand known for its quality and service.

Installation and Maintenance Tips

Proper installation and regular maintenance are crucial for the longevity and performance of self-priming pumps.

Proper Installation Procedures

Follow manufacturer guidelines for installation to ensure optimal performance and avoid common issues. A proper installation can lead to operational inefficiencies and premature wear. Ensure the pump is installed on a stable and level surface, with proper alignment to the piping system.

Regular Maintenance Practices

Schedule regular inspections and maintenance to identify and address potential problems early. Regular maintenance ensures that the pump operates efficiently and has a longer lifespan. Maintenance tasks may include checking for leaks, inspecting the impeller for wear, and lubricating moving parts.

Troubleshooting Common Issues

Please familiarize yourself with common issues such as air leaks, cavitation, and clogging and their solutions to minimize downtime and maintain efficiency. A troubleshooting guide and the necessary tools can help quickly resolve issues and prevent prolonged downtime.

Extending the Lifespan of the Pump

Implement best practices for operation and maintenance to extend the pump’s lifespan and reduce costs. This includes regular cleaning, lubrication, and parts replacement. Ensure that the pump is only operated under conditions within its specifications, which can cause premature failure.

Innovations and Trends in Self-Priming Pump Technology

Recent advancements in self-priming pump technology have led to significant improvements in performance and efficiency.

Advancements in Design and Materials

Innovations in pump design and materials have enhanced durability, efficiency, and compatibility with various fluids. Modern materials resist corrosion and wear better, extending pump life. New designs also focus on improving the self-priming capabilities, making pumps more reliable in challenging conditions.

Smart Pumps and IoT Integration

Integrating innovative technology and IoT allows real-time monitoring and control, improving efficiency and reducing maintenance costs. Intelligent pumps can provide data on performance, predict maintenance needs, and improve overall system efficiency. This technology helps optimize pump operations, reduce energy consumption, and prevent failures.

Sustainable and Eco-Friendly Pump Solutions

New environmentally friendly materials and energy-efficient designs contribute to sustainability and reduce the environmental impact. These innovations help industries meet environmental regulations and reduce their carbon footprint. For example, pumps made from recyclable materials and those designed to use less energy are becoming increasingly popular.

Case Studies and Real-World Examples

Several industries have benefited from self-priming pumps, showcasing their versatility and efficiency.

Industrial Applications

Chemical Processing Plants

Self-priming pumps have improved operational efficiency and reduced maintenance costs by efficiently handling corrosive and abrasive fluids. For instance, a chemical plant replaced its traditional pumps with self-priming pumps, resulting in a 30% reduction in maintenance downtime and a 20% increase in overall efficiency.

Wastewater Treatment Facilities

These pumps efficiently manage sludge and other challenging materials, reducing downtime and maintenance requirements. A wastewater treatment plant reported a 25% increase in processing capacity and significant cost savings after switching to self-priming pumps.

Agricultural Applications

Irrigation Systems

With self-priming pumps used for irrigation, farmers have experienced increased productivity and reduced water wastage. Consistent water supply is crucial for crop health and yield. A large farm in California noted a 15% increase in crop yield after implementing self-priming pumps for its irrigation system.

Slurry Handling

Self-priming pumps efficiently handle manure and other slurry materials, improving farm waste management practices. A dairy farm in Wisconsin improved its slurry management system, reducing labor costs by 20% and increasing operational efficiency.

Construction Projects

Dewatering Sites

Construction sites have achieved faster dewatering, ensuring projects stay on schedule and preventing water-related delays. A significant construction project in Florida reported a 40% reduction in dewatering time using self-priming pumps, allowing the project to be completed ahead of schedule.

Concrete Pumping

Timely and efficient concrete delivery is crucial in construction. Self-priming pumps ensure consistent concrete supply, improving project timelines. A construction company in New York saw a 25% increase in project completion speed due to the reliable performance of self-priming concrete pumps.

Marine Applications

Bilge Pumping on Ships

Efficient bilge pumping is essential for maintaining safety and preventing water accumulation in vessels’ bilges. A shipping company operating in the Mediterranean improved its fleet’s safety record by 30% after upgrading to self-priming bilge pumps.

Ballast Water Management

Ships have enhanced stability and safety through efficient ballast water management using self-priming pumps. This is crucial for compliance with international maritime regulations. A large cargo ship company noted a significant improvement in ballast management efficiency and compliance with environmental standards.

Conclusion

Due to their efficiency, ease of use, and versatility, self-priming pumps are essential in various industries. Businesses can make informed decisions and optimize their fluid handling processes by understanding their advantages, applications, and recent innovations. DAE Pumps offers a range of high-quality self-priming pumps designed to meet diverse needs, providing reliable solutions for efficient fluid management.

Contact DAE Pumps today for further information and expert advice on selecting and using self-priming pumps and discover how we can help with your pumping needs.